FICHA TÉCNICA

CLASS

Det Norske Veritas, Malta Cross 1 A 1 Column-Stabilized Drilling Unit, Drill, Heldk, Crane, E0, DYNPOS, AUTRO

BUILT BY

Daewoo Shipbuilding & Marine Engineering Co, Korea, in 2011

Variable Deck Load Capacity

Operation Draft 9.799 Ton Transit Draft 7.432 Ton

LIVING QUARTERS

200 persons

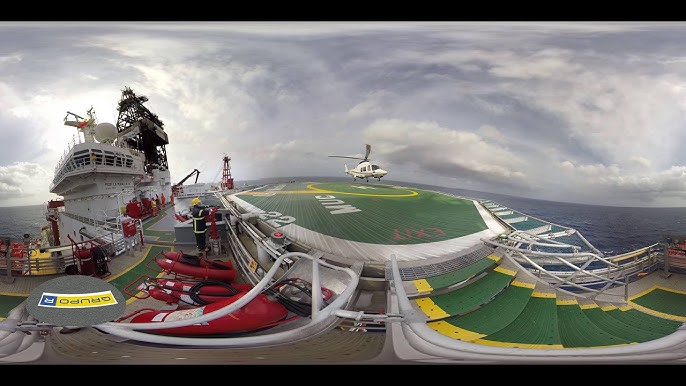

HELLDECK

Sirosky S-61 and S-92 with helicopter refueling system

MAIN DIMENSIONS

Length Over all - 119.20 m / Beam Over all - 96.70 m / Height Base line to Upper Deck - 42.5 m

STORAGE CAPACITIES

Riser storage área 860 m2 Deck área 7.293 m2 Drill pipe and casing setback 12.000 m

DRAFTS

Normal Operation 23.00 m / Survival 19.00 m / Transit 9.94 m

DYNAMIC POSITIONING SYSTEM (DPS)

DNV DYNPOS AUTRO (DP Class 3). Redundancy based on three DP control stations and a segregate back up room with a DP control station, including DGPS and hydroacoustic postion reference system

AZIMUTH THRUSTERS

Eigth (8) Flowserve WF SD-350-3500, azimuthing 360 degrees, 3500 Kw each connected to the DP, DYNPOS AUTRO (DP Class 3)

POWER

Eight (8) Caterpillar C-3616 main engines with generators with an output of 4.700 KW each arranged in four segregated engine rooms, as per DP3 requirement. One Dead Ship Generator (350 Kw) installed in a separated room

MAIN CRANES

Two cranes of 80 Ton each

AIR COMPRESSORS

Three (3) Service compressors, 1500 m3/h each at 8 bar pressure Two (2) Starting air compressors 195 m3/h each

FRESH WATER GENERATOR

Two (2) vapor compression type with capacity for 50 m3/day each

SEWAGE TREATMENT PLAN

Two (2) units with capcity for total service to 200 persons

LIFE SAVING EQUIPMENT

Four (4) lifeboats fully enclosed, diesel engine driven, capacity for 100 men each One (1) high speed rescue boat diesel engine driven for 9 men Twelve (12) Life-rafts for 35 men each

COMMUNICATION SYSTEM

GMDSS Radiostation including emergency radio equipment VSAT satellite communication system

DERRICK

Dynamic type Derrick rated for 2.000.000 lbs static hook load

CROWN BLOCK

2.000.000 lbs capacity with eight 72” sheaves for 2” drill line

DRILL STRING COMPENSATOR

Crown mounting compensator Max Compensating load capacity 1.000.000 lbs Compensating stroke 25 fts Also includes an Active Heave compensator

TRAVELING BLOCK

Capacity for 2.000.000 lbs capacity with seven 72” sheaves for 2” drill line

TOP DRIVE

2.000.000 lbs capcity, speed range 0-240 rpm, máximum torque 87.020 lbs-feet, 2 AC motors 1.150 HP each

DRAWWORK

One drawwork 4.500 HP Rotary Table 60 ½” rotary table hydraulically driven, capacity 2.000.000 lbs

DRILLER CONTROL ROOM

One drill control cabin with drilling instrumentation and controls for drill floor and derricks equipment, remote inidcation of relevant drilling parameters, driller and assistant driller control chairs

Drill String and Pipe Handling Equipment

Remotely controlled and operated drill string and pipe handling system with tubular racking system for casing and drill string, fingerboard for vertical racking, hydraullic roughneck (two) Power slips

Riser and Pipe Handling Equipment

Riser Gantry Crane, riser feeding machine, drill floor manipulator arm, pipe deck pipe handler, tubular feeding machine

Well Control Equipment

One Cameron TL 18 ¾”, 15,000 psi, H2S resistant including: Two 18 ¾” DL annular preventer, 10,000 psi One double 18 ¾” TL ram preventer, 15,000 psi WP (shear blind and super shear)

BOP Control System

One set of multiplex Electro-hydraulic BOP Control System includin Surface hydraulic poer unit, Surface and subsea accumulators units, control panels, subse system with two control PODs, two mux cable, and cable riels, hot line hose and reel, riser fill up vlve and accoustic system for 10,000 ft

BOP and X-TREE MH Handling Equipment

BOP & LMRP transporter 520 TM BOP Crane 2x75 TM (150 TM) X-MAS TREE Overhead crande and trolley, 200 TM

Choque and Kill Manifold

Pressure rated for 15,000 psi W.P., 3 1/6” ID, includes two manual and two hydraulic operated chokes, rated for H2S Service, with 2 remote choke control panel

DIVERTER

With pressure energized seals, to be installed in the 60 ½” rotary table, rated for 500 psi with 16” Flow lines and valves and remotely operated hydraulic control panel.

RISER TENSIONING SYSTEM

3.500.000 lbs capacity (1.587,5 TM) in six tensioning cylinders with máximum stroke of 50 feet

MUD PUMPS

Four (4) with Triplex Mud Pumps 2,200 HP each, 7,500 psi max pressure, 884 gpm max Flow rate each, and four Mission super charger pumps

SOLIDS CONTROL EQUIPMENT

Six (6) double check sale shakers capacity, 529 gpm (120 m3/h) One desiter unit 20 cones 12”, 50 – 600 gpm capacity One desander two cones 12”, 1200 gpm capacity Two degassers 1200 gpm capacity each One mud-grass separator Two centrifugal decanting units

OTHER EQUIPMENT

Mud Laboratory Room Cementing Unit CPS-665, 1720 HP, Mixer of 100 Bls ROV, Subsea 7, Quantum WROV, 230 HP 10,000 ft Emergency monitoring system, Two 18,8 Ton Anchors 928 m mooring